Aramid Fiber for Welding Blankets? Is it a good choice? In industrial welding, temperatures often go above 200°C, so safety is key. If the welding blanket manufacturers need to produce a welding blanket that’s lightweight, heat-resistant, durable, flame-retardant, and foldable, aramid fiber is the best option. As a leading manufacturer of high-quality aramid fibers, we provide the ideal material for welding blankets that deliver unmatched safety, durability, and performance. We’re here to show you why aramid is the ultimate choice for welding blanket manufacturers who want to deliver unmatched safety, durability, and performance. In this article, we will share with you: What is aramid fiber? As a Welding Blankets Manufacturers How to Choose Aramid Filament or Aramid Twisted Yarn? Why Aramid Fiber Better for Welding Blankets? Aramid-based welding blankets in industrial applications, welding blanket manufacturer.

What is Aramid Fiber?

Aramid fiber is a high-performance synthetic material known for its incredible strength and heat resistance. Brands like Kevlar® and Twaron® are some of the most well-known names in this category. For welding blanket manufacturers looking for high-performance materials, technical textile, there’s now another excellent option: “AramidX.” You can find para-aramid 1414 as a material for welding blankets. As a trusted manufacturer of aramid fibers, it is the go-to choice for applications where durability, flame resistance, and extreme condition performance are key.

Key Properties of Aramid Fiber:

Chemical Resistance: It resists harsh chemicals, making it ideal for tough environments.

Unmatched Strength: It’s stronger than steel by weight, making it perfect for heavy-duty use.

Heat Resistance: It can withstand continuous temperatures up to 200°C and can endure even higher temperatures for short periods.

Flame Retardant: Aramid fiber is self-extinguishing and won’t melt or drip when exposed to flames.

Lightweight: Despite its strength, it remains surprisingly light and easy to handle.

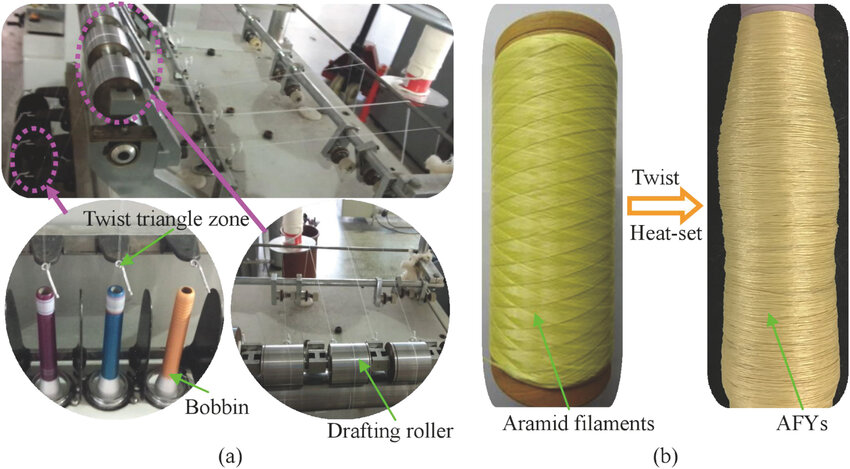

Welding Blankets Manufacturers How to Choose: Aramid Filament or Aramid Twisted Yarn?

When making welding blankets, choosing between aramid filament and aramid twisted yarn depends on your specific needs, performance requirements, and production process. Here’s a comparison and recommendation:

1. Aramid Filament

Features:

- High Strength: Great for applications needing strong mechanical performance.

- Smooth Surface: Easy to process and coat.

- Lightweight: Perfect for lightweight welding blankets.

- Heat Resistant: Excellent for high-temperature environments.

Best For:

- Welding blankets that need high-strength and lightweight properties.

- Welding blankets require a smooth, easy-to-coat surface.

- High-end industrial uses, like aerospace and shipbuilding.

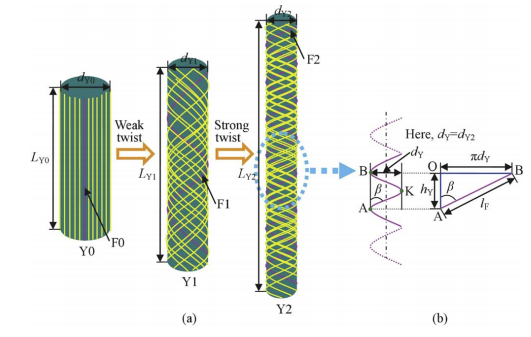

2. Aramid Twisted Yarn

Features:

- Wear Resistance: Twisted structure makes it more durable in high-friction environments.

- Flexibility: Softer and easier to weave or sew.

- Cost-Effective: Usually cheaper to produce than filament.

- Tear Resistance: Twisted structure improves tear resistance.

Best For:

- Welding blankets that need high wear and tear resistance.

- Welding blankets requiring flexibility and easy sewing.

- General industrial uses, like construction and automotive repair.

Which Should You Choose?

- High-End Applications (e.g., aerospace, shipbuilding):

- Use Aramid Filament for its high strength and lightweight properties.

- General Industrial Applications (e.g., construction, automotive repair):

- Use Aramid Twisted Yarn for its wear resistance and cost-effectiveness.

- Special Needs:

- If you need a smooth surface or coating, choose Aramid Filament.

- If you need high wear resistance or tear resistance, choose Aramid Twisted Yarn.

More information, please check Aramid filament vs aramid twisted yarn

Aramid Fiber Better for Welding Blankets

Welding blankets are a must-have when it comes to keeping workers and equipment safe from sparks, heat, and flames. But if you want to make sure they do the job right, it’s all about choosing the right material. Here’s why aramid fiber is the perfect fit for a welding blanket manufacturer:

Top-Notch Heat Protection

Welding produces intense heat. They offer excellent thermal insulation, protecting both people and equipment from heat risks.

Heat-Resistant Materials You Can Trust

Aramid fibers don’t catch fire easily. They’re naturally flame-resistant, making them a smart choice for welding blankets that need to guard against fire hazards in high-risk environments.

Built to Last

Aramid fibers can handle tough conditions without breaking down. That means welding blankets made with aramid last longer, saving you on replacement costs and reducing downtime in your operation.

Light and Flexible

Unlike bulky materials, aramid fibers are lightweight yet strong. They’re easy to handle, transport, and store, without compromising on performance.

Tailored to Your Needs

Whether you need a specific thickness, weight, or a special coating, aramid fibers can be customized to meet the demands of your welding applications.

Industrial Safety Solutions—aramid-based welding blankets in industries like:

- Automotive: Protecting vehicles and equipment during repairs.

- Construction: Shielding structures and workers on the job.

- Shipbuilding: Reducing fire risks in tight spaces.

- Aerospace: Keeping workers safe during precise welding tasks.

- Metalworking: Protecting machines and people in fabrication shops.

Welding Blanket Manufacturer‘s Benefit—Why Us?

We’re not just another supplier—we’re the right partner for your aramid fiber needs. Here’s why:

Always Here for You: Our experts are always available for technical advice and after-sales support.

Quality You Can Count On: Our aramid fibers meet all the international standards and go through thorough testing to ensure maximum performance.

Made-to-Order: We provide custom fibers to suit your exact specifications, whether it’s size, thickness, or finish.

Fair Pricing: As a direct manufacturer, we offer competitive prices without cutting corners on quality.

Worldwide Reach: We ship globally and offer fast, reliable delivery.

A Success Story

One of our clients—a leading welding blanket manufacturer:

Ater switched to our aramid fibers for their premium line. The results were outstanding

- 30% increase in durability: Their blankets stood up better in high-heat conditions.

- Better safety: The flame resistance kept workplace incidents down.

- Happier customers: End-users loved how lightweight yet tough the blankets were.

Let’s Get Started

Ready to choose our aramid fiber for welding blankets? Contact us today for a sample or custom quote. We’re here to help you create better, safer, and longer-lasting welding solutions for your customers.

Get in Touch:

Email: aramidfiberx@gmail.com

Aramid fiber isn’t just another material—it’s a game-changer for welding blankets. Its unbeatable heat resistance, flame resistance, and durability make it the ideal choice for industrial use. Partner with us, and you’ll get more than just a supplier—you’ll get a team committed to your success

Let’s make welding safer and more reliable. Reach out today!